P2 Mk2 and P4 Mk1 Anti-Personnel Landmines (Pakistan)

Two Pakistani P4 series anti-personnel blast mines (brown plastic casings with a yellow band) recovered in Sri Lanka. The left mine’s pressure plate was triggered (depressed) but failed to detonate; its baseplate (below) shows the detonator and booster charge. (Noland Landmines)

Specifications

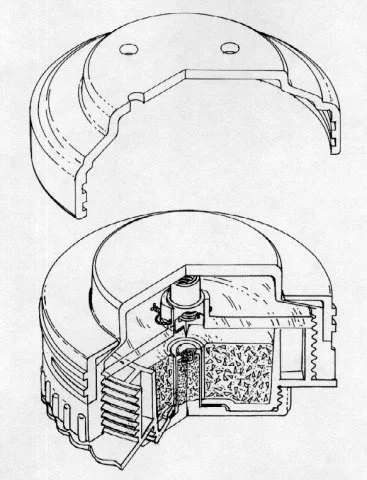

The P2 Mk2 and P4 Mk1 are small, pressure-activated anti-personnel blast mines produced by Pakistan Ordnance Factories (POF) (Human Rights Watch). Both are minimal metal mines with plastic casings. They are roughly disc-shaped, about 70 mm in diameter and 40 mm in height), and weigh only a few hundred grams each. The main explosive charge is relatively small – on the order of tens of grams of high explosive (approximately 30 g of Tetryl in the P4 mine) (Noland Landmines).

Triggering Mechanism: Both mines use a simple pressure fuze. The top of the mine is a round pressure plate. When roughly 5–10 kg or more of force (e.g. a person’s footstep) is applied, a thin shear wire inside breaks, releasing a spring-loaded firing pin that snaps into a detonator. This ignites a booster and then the main charge, causing a blast directed upward. The explosion can severely wound the victim’s foot or leg. The mines are non-fragmenting (they rely on blast effect only, with no metal shrapnel). A plastic safety cap covers the pressure plate during transport and is removed to arm the mine. Deminers can neutralize the mine by replacing the safety cap or carefully unscrewing the base to remove the detonator/booster.

Construction and Use: The P2 Mk2 and P4 Mk1 have brown or olive-green bodies, often with a yellow band where the top and bottom halves join. They contain almost no metal (aside from a tiny spring or pin), making them hard to detect. Uniquely, these mines can also serve as the fuze for larger anti-tank (AT) mines: Pakistani AT blast mines like the P2 Mk2 (AT) and P3 Mk2 have a cavity for inserting a P2 or P4 AP mine as the trigger charge (Bulletpicker). When a vehicle crushes the AT mine’s pressure plate, it sets off the embedded P2/P4, which in turn detonates the anti-tank mine’s main charge (Bulletpicker). This dual-use design means the P2 Mk2 and P4 Mk1 perform two roles: as standalone anti-personnel mines and as the initiating charge (fuze/booster) in Pakistan’s anti-vehicle mines.

Similar Items

Many other countries have developed small, minimal-metal AP blast mines with comparable characteristics:

U.S. M14 “Toe-Popper”: A tiny cylindrical blast mine (~56 mm diameter, 40 mm high) containing 29 g of Tetryl explosive (Noland Landmines). It has a plastic body with only a small metal firing pin, making it very hard to detect (Noland Landmines). The M14’s trigger is a pressure plate (activation force ~9–16 kg) and it was designed to maim the victim’s foot, similar to the P2/P4 mines.

Chinese Type 72 (non-metallic): A small Type 72 AP blast mine used in Asia (not to be confused with the larger Type 72 AT mine). It has a plastic body and around 50 g of explosive (TNT). The Type 72 is a minimal-metal design similar to the Pakistani mines, known from conflicts in Afghanistan and Southeast Asia.

Manufacturing and Deployment

These mines are manufactured by the state-owned Pakistan Ordnance Factories (POF), which by the 1990s was producing at least six types of AP mines including the P2 Mk2 and P4 Mk1. The P2 Mk2 and P4 Mk1 were produced in significant quantities during the Cold War and afterward, primarily for Pakistan’s own defense needs. In the past, Pakistan also exported AP mines; it was regarded as one of the most prolific suppliers of mines to conflict zones before the late 1990s. Pakistani-made P2/P4 mines have been found in numerous countries, often via arms transfers to allied governments or armed groups. For example, these mines have turned up in Afghanistan, Angola, Somalia (Somaliland), Eritrea, Ethiopia, Sri Lanka, and along the India-Pakistan border.

Deployment in Conflicts

Pakistan itself has used these mines in conventional warfare and border defense. The Pakistani Army laid extensive minefields during its wars with India in 1947–48, 1965, and 1971, and has also emplaced mines along portions of the Line of Control in Kashmir (Human Rights Watch). It is reported that P2/P4 mines were among those used in these defensive minefields. In the 1980s, during the Soviet–Afghan War, Pakistan supplied Afghan mujahideen fighters with mines and also used mines to secure its own tribal areas (some border bases in Pakistan’s FATA were mined by mujahideen to prevent Soviet incursions) (Human Rights Watch). In the late 1990s, there were allegations that Pakistani-manufactured AP mines were covertly supplied to militant fighters during the Kargil conflict (1999) in Indian-administered Kashmir (Human Rights Watch). Indian forces recovering mines in Kashmir have on occasion identified Pakistani POF markings on some devices (Human Rights Watch). Additionally, Sri Lankan military forces and the LTTE rebels both encountered P4 series mines during the Sri Lankan civil war, suggesting either direct use by Sri Lankan government (which had defense ties with Pakistan) or transfer via third parties.

History and Development

The P2 Mk2 and P4 Mk1 mines were developed as part of Pakistan’s indigenous landmine program during the Cold War. Pakistan’s early antipersonnel mines were likely modeled after foreign designs (the P2 and P4 resemble other NATO and Warsaw Pact blast mines of the 1950s–60s). By the 1970s, Pakistan was mass-producing these mines. The P2 Mk2 appears to be one of Pakistan’s first plastic AP mine designs, and the P4 Mk1 was a subsequent model. The numbering suggests that the P4 Mk1 came after the P2 in development, possibly introducing some design improvements. For instance, the P4 Mk1’s use of Tetryl and a screw-on safety cap may have been incremental upgrades. Both types were in service by the time of the 1971 Indo-Pak war, and they continued to be produced into the 1980s and 1990s.

Detection Difficulty

Because the P2 Mk2 and P4 Mk1 were originally minimal-metal mines, they are notoriously difficult to detect with standard metal detectors. The only metal components in these mines are very small (a spring, striker, or shear pin) (Noland Landmines). A demining report notes that the total metal in a P4 mine amounts to just a twisted sliver of wire and a tiny igniter – insufficient for many detectors to pick up (Noland Landmines). Landmine Monitor classified the P2 Mk2 and P4 Mk1 as “non-detectable mines” in their original form (Landmine Monitor Report 2000. This means humanitarian demining teams must often resort to prodding or advanced methods (like ground-penetrating radar or sniffing dogs) to find them, since a typical magnetic detector may not alarm on these plastic mines.

To address this, Pakistan in 1997 began providing removable metal detector rings with new production mines. The idea is that a steel ring or washer can be fitted around the mine or inside it to ensure a metal detector will sense it. In practice, however, these rings were “rarely used in the field” – either soldiers omitted them when laying mines, or older mines already in the ground never had them. As a result, many P2/P4 mines encountered in conflict zones remain effectively undetectable by conventional detectors. Pakistan’s compliance with CCW Protocol II led to the P4 Mk2 variant, which incorporates a metal disk to meet detectability standards (P3 Mk2 mine - Wikipedia), and Pakistan has reported retrofitting steel discs into stockpiled older mines (P3 Mk2 mine - Wikipedia). Even so, any mines of these types laid in past decades without the added metal continue to pose a serious detection challenge.

Images and Additional Information

This photograph was taken at DDG - Danish Demining Group in Maruthamadu GN division close to Omantai Checkpoint storage pit of the Rangan 99, a similar clone to the P4 MK1.

P4MK1/ P2MK2 Related Accidents

Below is a summary of accident reports from the Humanitarian Demining Accident and Incident Database (HD-AID), maintained by the Center for International Stabilization and Recovery at James Madison University. They detail specific incidents involving the P2 Mk2 and P4 Mk1 anti-personnel blast mines in Sri Lanka, primarily around the Jaffna and Batticaloa regions. Here is a summary of the key points found in these reports:

Mine Types:

P2 Mk2 and P4 Mk1 Anti-Personnel Blast Mines

Locations and Context:

Most incidents occurred in Sri Lanka, specifically in:

Jaffna District (including Valikamam South, Mallakam, and Erlalai)

Batticaloa District (including Periya Pullumalai)

Mannar District (Vankalai)

These areas were minefields laid as defensive barriers, typically by the Sri Lankan Army (SLA), to protect forward defensive lines (FDLs).

Accident Causes:

Most accidents were classified as either excavation or handling accidents.

Primary causes included:

Victim inattention

Inadequate training

Field control inadequacy

Unavoidable incidents (e.g., concealed or missed mines during clearance)

Common Conditions and Tools Involved:

Mines were typically concealed in soft soil, grassy areas, or mixed terrain with small rocks.

Deminers commonly used tools such as heavy rakes to excavate mines or verify cleared areas. This often triggered mines unintentionally.

Injuries:

Injuries ranged from minor (superficial cuts and temporary sensory loss) to severe (amputations, fractures, and permanent disabilities).

PPE (personal protective equipment) was usually worn but sometimes inadequately or improperly used (visors raised or not worn), contributing to the severity of injuries.

Detection and Challenges:

Detection of these mines is particularly difficult due to their minimal metal content. This necessitated cautious excavation methods, but incidents occurred despite these precautions.

Mines were sometimes set off accidentally during the handling or excavation process.

Investigation and Reporting:

Reports were typically internal investigations conducted by humanitarian demining organizations involved, with occasional involvement from the National Mine Action Authority in Sri Lanka.

Recommendations from these investigations generally emphasized improved training, stricter adherence to standard operating procedures (SOPs), better field management, and the consistent and correct use of PPE.

Recommendations and Insights:

The use of longer tools, such as extended rakes, sometimes reduced injury severity.

Incidents underline the need for meticulous procedures due to the challenges posed by low-metal-content mines.

Many accidents highlighted issues with inattention, inadequate field control, and procedural lapses.

Report List

https://commons.lib.jmu.edu/cisr-globalcwd/736/

https://commons.lib.jmu.edu/cisr-globalcwd/637/

https://commons.lib.jmu.edu/cisr-globalcwd/663/

https://commons.lib.jmu.edu/cisr-globalcwd/739/

https://commons.lib.jmu.edu/cisr-globalcwd/616/

https://commons.lib.jmu.edu/cisr-globalcwd/735/

https://commons.lib.jmu.edu/cisr-globalcwd/641/

https://commons.lib.jmu.edu/cisr-globalcwd/623/